Instructions for Use of Gas Engine Filter Cartridges

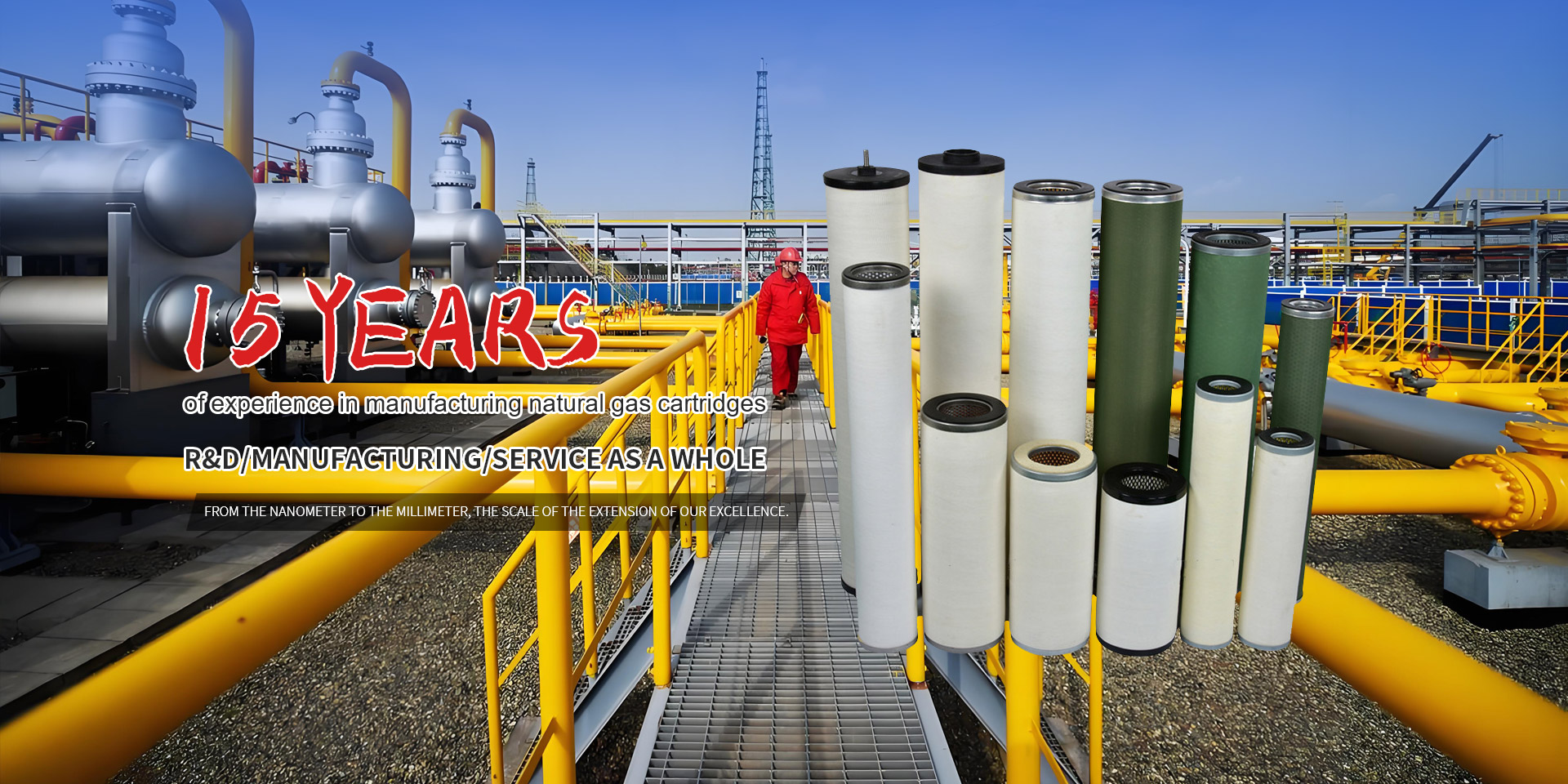

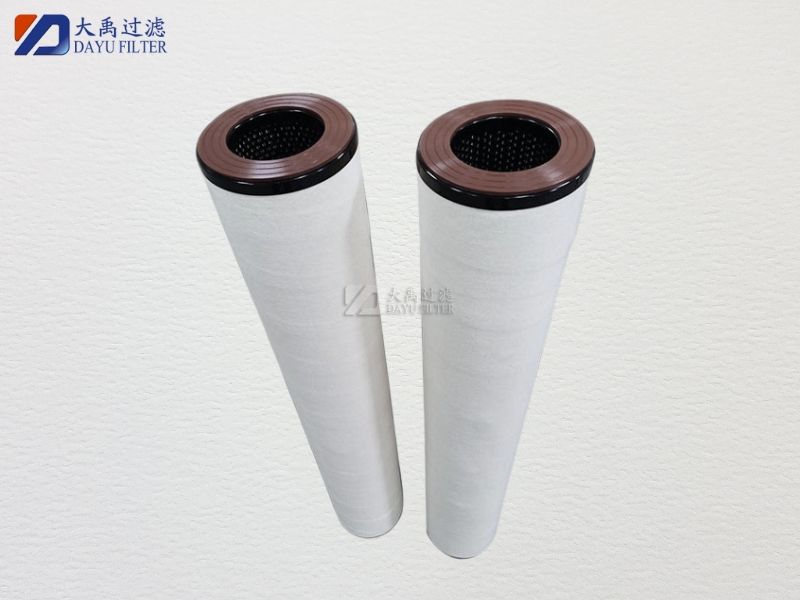

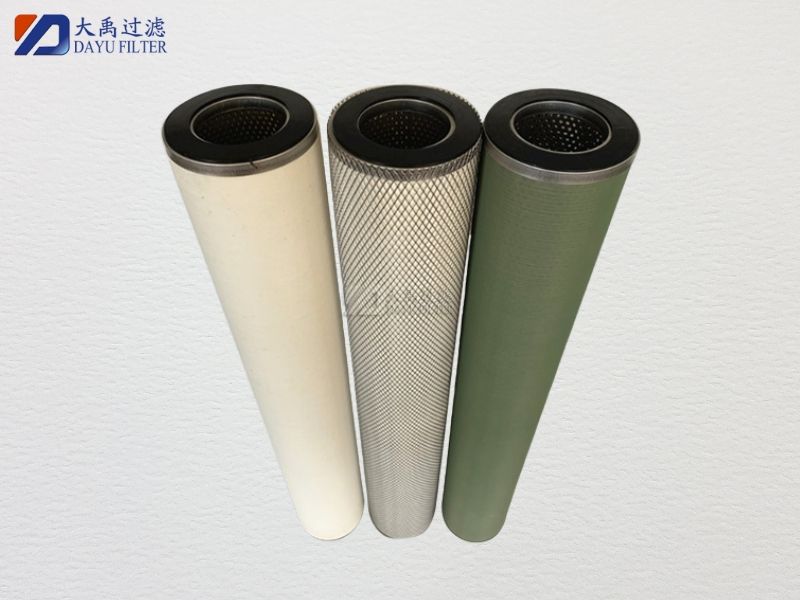

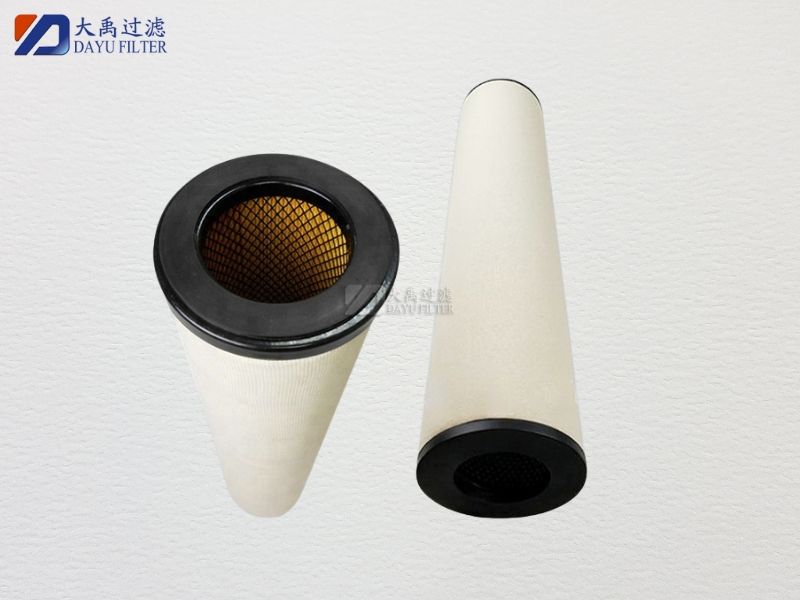

Gas engine filters are critical components in the intake and lubrication systems of gas engines (typically fueled by natural gas, biogas, liquefied petroleum gas, etc.), playing a vital role in engine performance, efficiency, and longevity. They are primarily divided into two categories: air filters and oil filters (gas filtration may also be involved, though gas is usually processed by a separate gas filter before entering the engine).Air FilterThis acts as the “mask” for gas engines, filtering air entering the combustion chamber.Functions:· Core function: Removes solid contaminants like dust, particulates, and sand from the air.· Engine protection: Prevents contaminants from entering cylinders, avoiding abnormal wear and scratches on critical components like pistons, cylinder liners, and valves.· Ensures Air-Fuel Ratio: Guarantees clean, stable airflow into the engine to maintain optimal air-fuel ratio, enabling more complete combustion, improved efficiency, and reduced emissions.Characteristics:· High Dust Holding Capacity: Accommodates greater dust accumulation, extending replacement intervals.· High Filtration Efficiency: Effectively filters extremely fine particles (typically over 99.9%).· Low Airflow Resistance: Designed to ensure smooth airflow without compromising engine intake efficiency.· Material: Typically constructed from specially treated filter paper (cellulose, synthetic fiber, or composite) with polyurethane end caps and sealing strips.Replacement Interval:· Depends on ambient air quality. Shorter intervals are required in dusty or high-dust environments.· Typically equipped with a differential pressure indicator (air filter warning device) that signals when clogging increases intake resistance beyond a threshold, indicating the need for cleaning or replacement.Oil Filter ElementThis serves as the engine's “kidney,” responsible for filtering impurities from engine lubricating oil.Functions:· Core function: Filters contaminants such as metal shavings, carbon deposits, and gummy substances generated during oil circulation to maintain oil cleanliness.· Protects the lubrication system: Clean oil effectively lubricates high-speed components like crankshafts, camshafts, and turbochargers, preventing wear and seizure.· Aids cooling: Clean oil facilitates better engine heat dissipation.Features:· Multi-layer filtration media: Typically uses materials like glass fiber or synthetic fibers with distinct filtration tiers to capture particles of varying sizes.· High-pressure and high-temperature resistance: Must withstand the oil system's high pressure and temperatures.· Bypass valve: Opens when low temperatures or clogging cause excessive oil pressure, allowing unfiltered oil to circulate (preventing oil starvation). This provides safety protection but leaves the engine unprotected during this period.Core FunctionThe bypass valve's core function is to ensure continuous engine lubrication with oil—even unfiltered oil—under extreme conditions. Its design philosophy is “lubrication with dirty oil is better than no lubrication at all.”Why is a Bypass Valve Necessary?During normal operation, the oil pump pressurizes oil through the filter paper, trapping contaminants like impurities and metal particles. Clean oil then flows to lubricate engine components.However, normal oil flow can be obstructed in two scenarios:Filter clogging: Over time, the filter element traps increasing amounts of debris, gradually blocking its pores and creating greater resistance to oil flow.Cold oil viscosity: During cold starts, especially in frigid conditions, oil temperature drops significantly, causing it to thicken (like syrup) and become highly viscous with poor flowability. Even with a brand-new filter, resistance remains extremely high under these conditions.In both scenarios, the oil pump must generate extremely high pressure to “push” oil through the filter. This can lead to:· Filter rupture: High pressure damages the filter's structure, causing it to tear or burst.· Overloading the oil pump: The pump must expend immense power, causing damage to itself.· The most severe issue: Oil cannot flow smoothly through the filter, depriving critical downstream engine components like the crankshaft, camshaft, and turbocharger of adequate lubrication. This leads to severe dry friction and overheating within minutes, causing catastrophic failures such as cylinder scoring and bearing seizure.How does a bypass valve work?The bypass valve is a safety pressure relief valve designed to address the aforementioned crisis.· Normal state (closed): When oil pressure is normal and can flow smoothly through the filter element, the pressure acting on the bypass valve is insufficient to overcome its spring preload, keeping the valve closed. All oil must pass through the filter paper.· Pressure Threshold: The bypass valve's opening pressure is precisely calculated (e.g., 1.5–3.5 bar, varying by engine) to ensure activation only when truly necessary.· Abnormal Condition (Open): When the pressure differential between the filter inlet (dirty oil side) and outlet (clean oil side) reaches the valve's preset opening pressure, high-pressure oil compresses the spring and forces the valve open.· Consequences: Once open, oil bypasses the clogged filter element, short-circuiting directly from the inlet to the outlet before entering the engine's main oil gallery.· Cost: The oil flowing to the engine at this point is unfiltered, containing contaminants and metal particles. These impurities act like “abrasives,” accelerating engine wear.Summary and AnalogyImagine it as an emergency fire escape:· Normal operation: Everyone passes through the main entrance (filter paper) in an orderly manner and undergoes security checks (filtration).· Emergency (fire/blockage): The main entrance becomes congested and impassable. To prevent greater disaster (engine seizure due to oil starvation), the emergency exit (bypass valve) is forcibly opened. This allows oil to evacuate rapidly, ensuring safety (engine lubrication). . While some impurities may bypass inspection, preventing immediate engine damage takes priority.Important Note:Bypass valve activation indicates a “fault condition”: your filter is severely clogged or the oil condition is abnormal. The engine is operating with a fault.Strictly adhere to oil change intervals: Use high-quality oil and genuine filters, replacing them within manufacturer-specified intervals. This is the fundamental method to prevent forced bypass valve activation.Avoid aggressive driving after cold starts: Especially in cold weather, idle for about one minute to allow oil temperature to rise and viscosity to improve. This reduces strain on the filter and lowers the risk of bypass valve activation.In summary, the bypass valve is a critical safety backup device. By making a “lesser of two evils” choice at critical moments, it prevents immediate, catastrophic engine failure. However, it also alerts users that the engine is operating under suboptimal conditions, necessitating timely maintenance.Replacement Intervals:· Typically aligns with engine oil change intervals. Strictly adhere to the engine manufacturer's recommended schedule (e.g., every 500 operating hours or annually).· Oil quality, engine load, and fuel quality all influence replacement intervals.Why Are Fuel Filter Elements So Critical for Gasoline Engines?Reduce Wear and Extend Overhaul Intervals: Clean air and oil are paramount for engine longevity. Effective filtration significantly extends overhaul intervals, saving substantial maintenance costs. As a professional filter element manufacturer, Xinxiang DAYU Filtering Equipment Co.,Ltd. provides engines with lasting protection through products featuring high dust-holding capacity, high filtration efficiency, and low resistance.Maintain power and efficiency: Clogged air filters cause insufficient air intake, leading to incomplete combustion, reduced engine power, and increased fuel consumption.Reduce emissions: Proper combustion minimizes harmful gas emissions (e.g., NOx, CO), meeting environmental standards.Prevent unexpected shutdowns: Regular filter maintenance avoids protective engine shutdowns caused by severe clogging, ensuring production continuity.Selection and Maintenance RecommendationsUse High-Quality Compatible Filters:· Never compromise on cost! Inferior filter media fail to deliver optimal filtration efficiency, dust-holding capacity, and service life. The resulting engine wear far exceeds the filter's value. Xinxiang DAYU Filtering Equipment Co.,Ltd filters utilize premium materials, ISO-certified, ensuring perfect engine model compatibility and reliable performance.· Ensure the filter element's specifications, dimensions, and filtration rating precisely match the engine model.Follow Prescribed Maintenance Intervals:· Strictly adhere to inspection and replacement schedules outlined in the engine manual.· For air filters, conduct more frequent checks in dusty environments (e.g., daily inspection of differential pressure indicators).Proper Installation:· Before installation, ensure the filter housing interior is clean and free of debris.· Inspect the sealing gasket for integrity to ensure a complete seal after installation, preventing unfiltered air from bypassing into the engine.Storage precautions:· Store spare filter elements in a dry, clean environment, avoiding moisture and contamination.SummaryThough small in size, gas engine filter elements serve as vital guardians protecting the engine's core. Investing minimal resources in maintenance prevents substantial losses caused by component wear, representing the most cost-effective approach to ensuring reliable, efficient, and long-lasting equipment operation. Leveraging its specialized expertise and premium products, Xinxiang DAYU Filtering Equipment Co.,Ltd has become the preferred partner for numerous gas engine users, supporting the long-term stable operation of their equipment.

2025-09-20