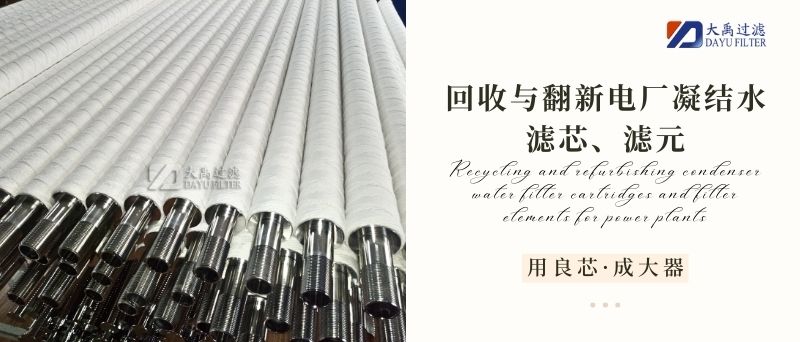

Recycling and refurbishing condenser water filter cartridges and filter elements for power plants

In the power industry, condensate water treatment is a critical process for ensuring water quality and maintaining the safe and stable operation of power generation units. As core components of condensate water treatment systems, filter cartridges and filter elements directly impact filtration efficiency and water quality safety. With the growing emphasis on environmental protection and the promotion of resource recycling, the recovery and refurbishment of condensate water filter cartridges and filter elements from power plants have become a focal point of industry attention.

I. Types and Characteristics of Filter Cartridges and Filter Elements

There are numerous types of filter cartridges and filter elements for power plant condensate water treatment. Based on differences in material and filtration principles, they can be categorized into wound filter cartridges, pleated filter cartridges, sintered tube filter elements, and others. Taking wound filter cartridges as an example, they are manufactured by winding high-performance fibers around a stainless steel skeleton, featuring high filtration efficiency, resistance to deformation, and minimal fiber shedding. Their length can reach up to 70 inches, with the central rod made of 304 or 316 stainless steel reinforcement, ensuring the overall strength and stability of the filter cartridge. Folded filter cartridges, with their high flow rate, large contaminant holding capacity, and ability to be backwashed, play a significant role in power plant condensate water treatment.

II. The Necessity of Recycling and Refurbishment

Resource Recycling: Filter cartridges and elements contain a significant amount of recyclable materials, such as stainless steel frames and high-performance fibers. Through recycling and refurbishment, these materials can be reused, reducing resource waste and lowering production costs.

Environmental Protection Requirements: Improper disposal of discarded filter cartridges and elements may cause environmental pollution. Recycling and refurbishment not only reduce waste generation but also prevent potential environmental hazards from harmful substances.

Economic Benefits: For power plants, recycling and refurbishing filter cartridges and elements can reduce procurement costs and improve economic efficiency. Additionally, by optimizing recycling processes and technologies, waste can be converted into valuable resources, creating additional economic value.

III. Technical Processes for Recycling and Refurbishment

1. Recycling Stage

Collection and Classification: Power plants should establish a comprehensive filter cartridge and element recycling system to uniformly collect and classify discarded filter cartridges and elements. Based on material type, size, and contamination level, they are categorized into three groups: recyclable, remanufacturable, and non-recyclable.

Preliminary Cleaning: Recyclable filter cartridges and elements undergo preliminary cleaning to remove surface oil residues and impurities, facilitating subsequent processing.

2. Refurbishment Stage

Disassembly and Inspection: Refurbishable filter cartridges and elements are disassembled to separate components such as frames and filter media. Professional equipment is used to inspect the components, assessing their performance and damage levels.

Cleaning and Repair: Components that pass inspection are thoroughly cleaned to remove internal dirt and residues. Damaged components, such as deformed frames or damaged filter media, are repaired or replaced.

Reassembly: Reassemble the cleaned and repaired components according to the original design requirements to ensure that the performance and structure of the filter cartridges and elements meet the standards.

Performance Testing: Conduct performance tests on the refurbished filter cartridges and elements, including filtration efficiency, pressure drop, flow rate, and other metrics. Ensure that the performance of the refurbished products meets or exceeds the original factory standards.

3. Resource utilization stage

Material extraction: For filter cores and elements that cannot be refurbished, extract recyclable materials such as stainless steel and high-performance fibers using specialized equipment and technology. These materials can be used to manufacture new filter cores, elements, or other products.

Waste Disposal: For waste that cannot be recycled, environmentally friendly disposal methods are employed, such as incineration for power generation or landfill. The disposal process complies with environmental protection requirements to prevent pollution.

IV. Practical Examples of Recycling and Refurbishment

Taking a large power plant as an example, the facility has established a comprehensive filter cartridge and element recycling and refurbishment system, achieving both resource recycling and enhanced environmental benefits.