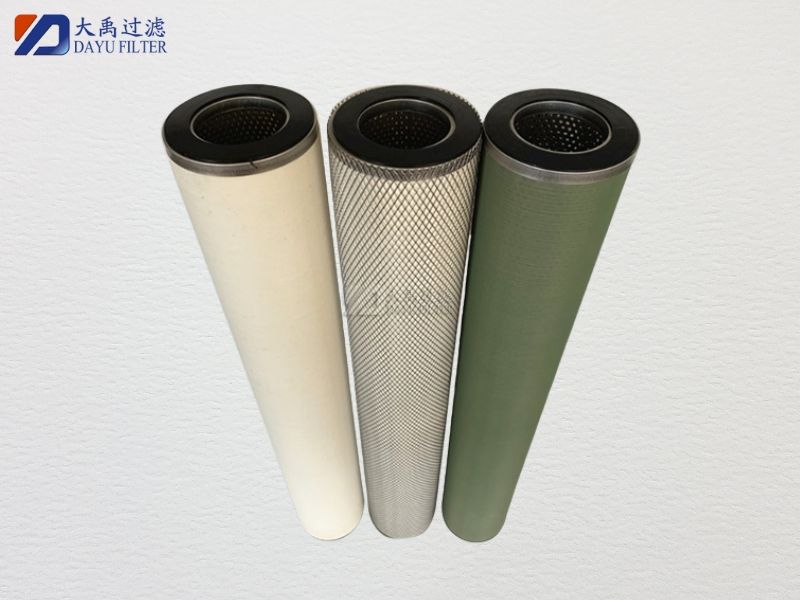

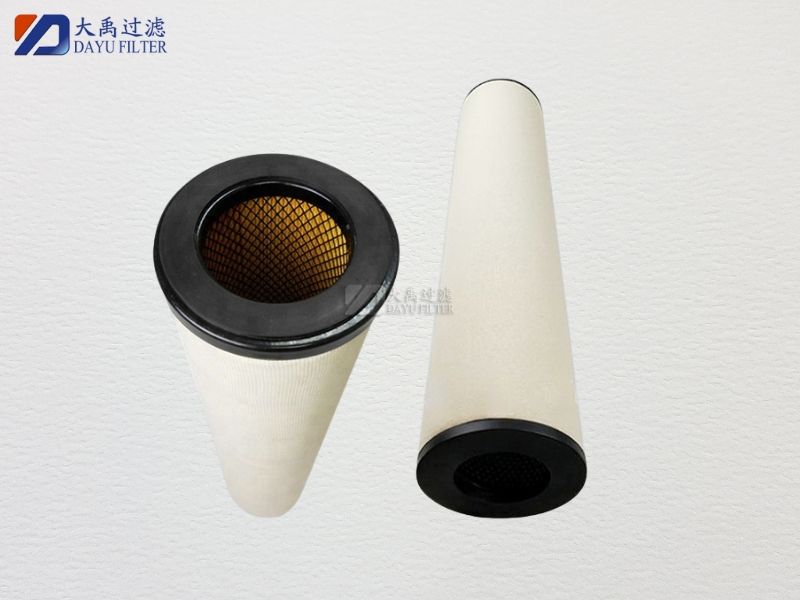

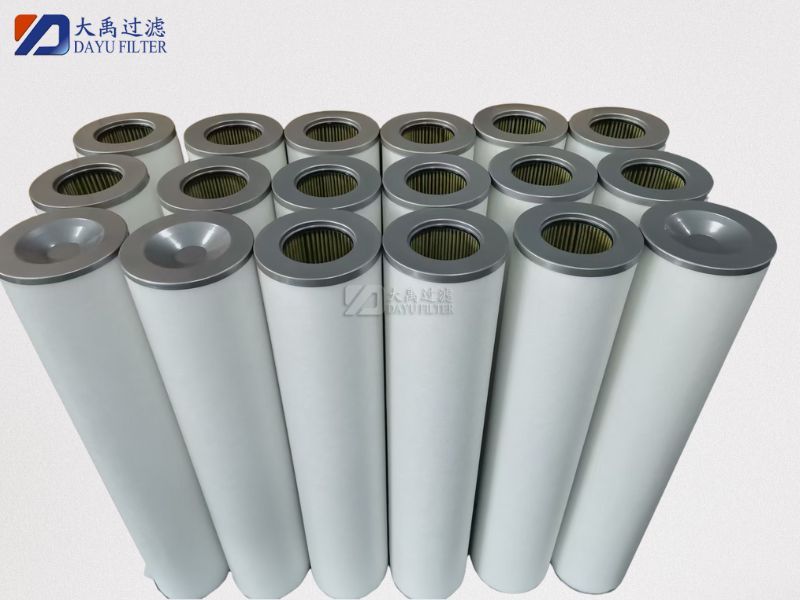

P600D series amine liquid filter cartridge P600D-650-M1-30LE

源头厂家

技术创新

高性价比

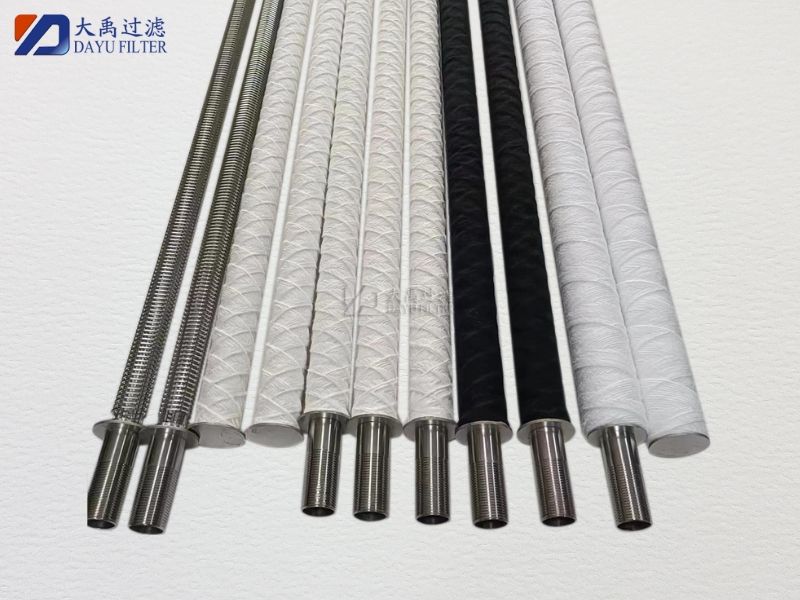

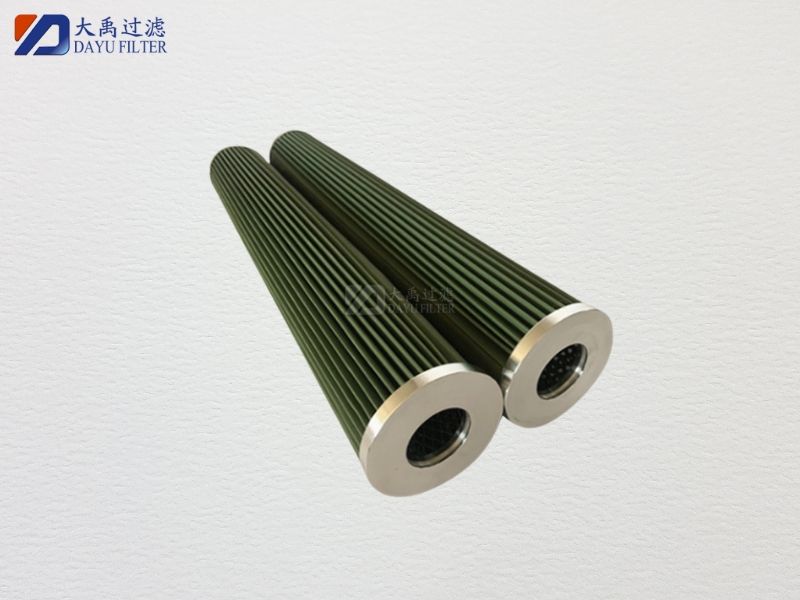

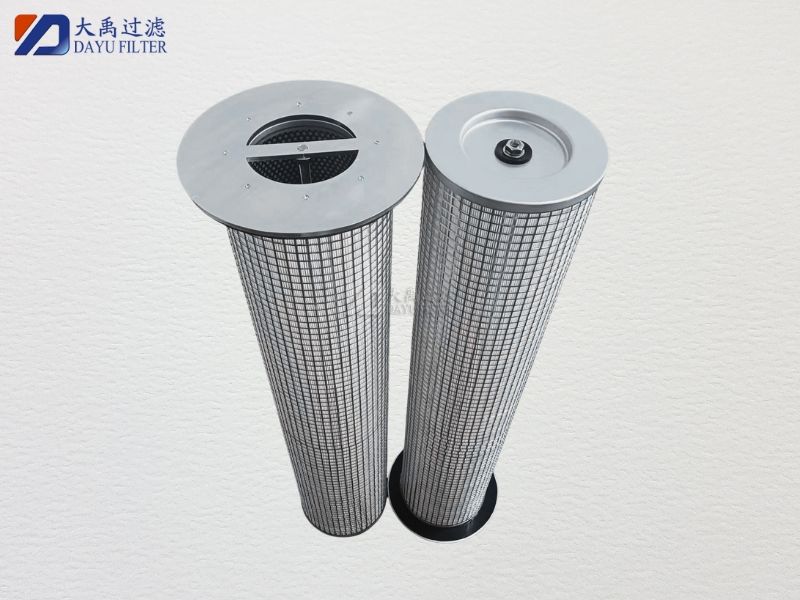

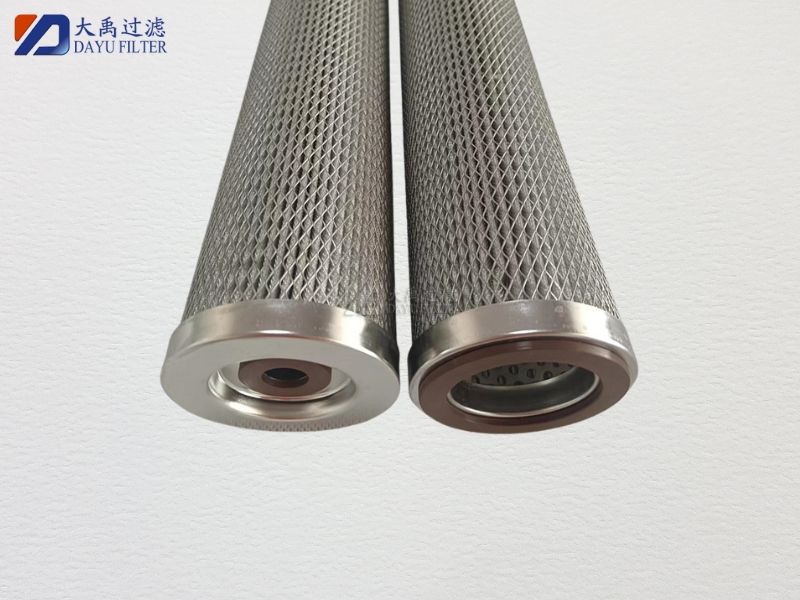

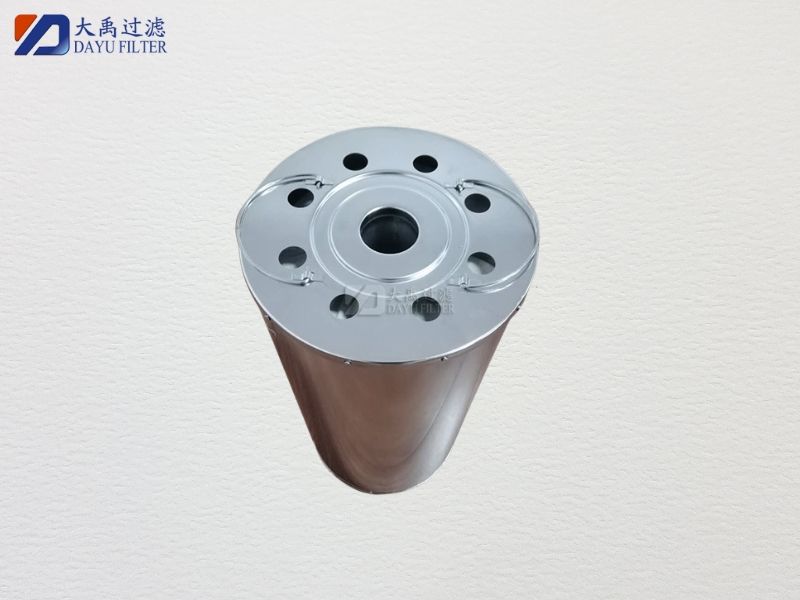

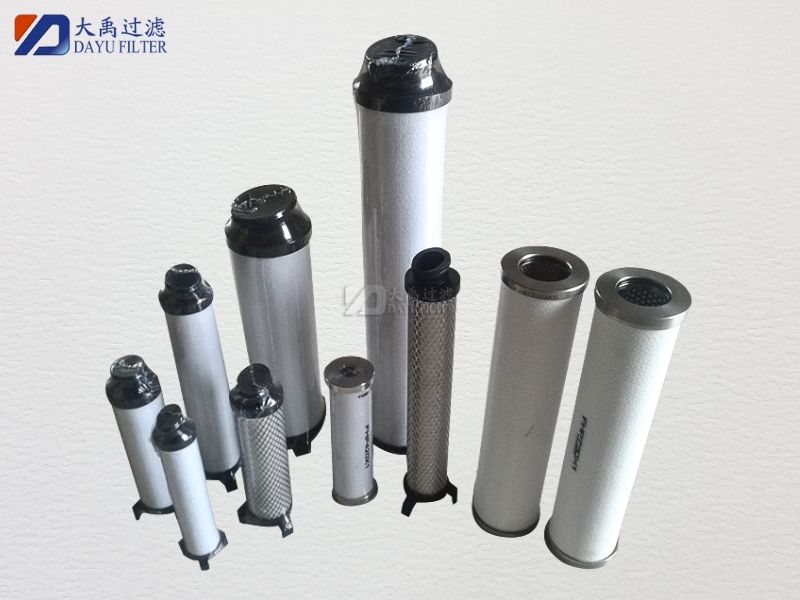

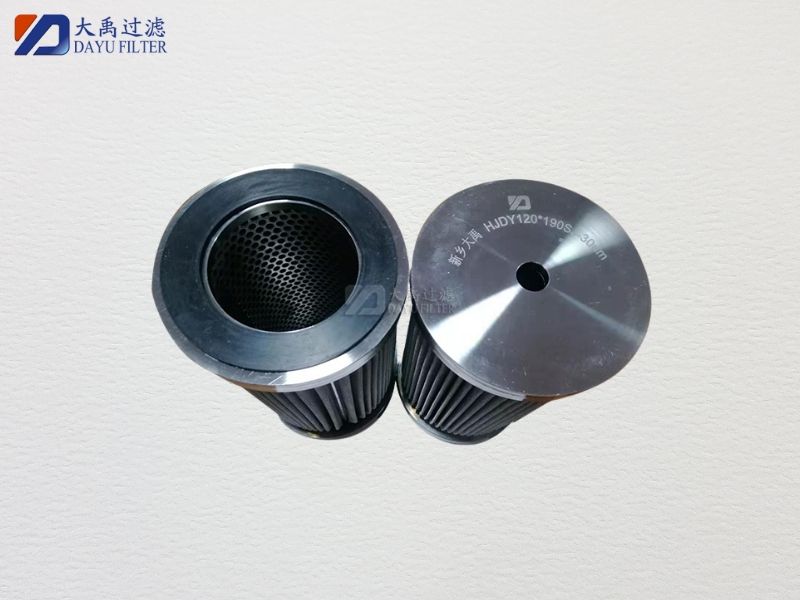

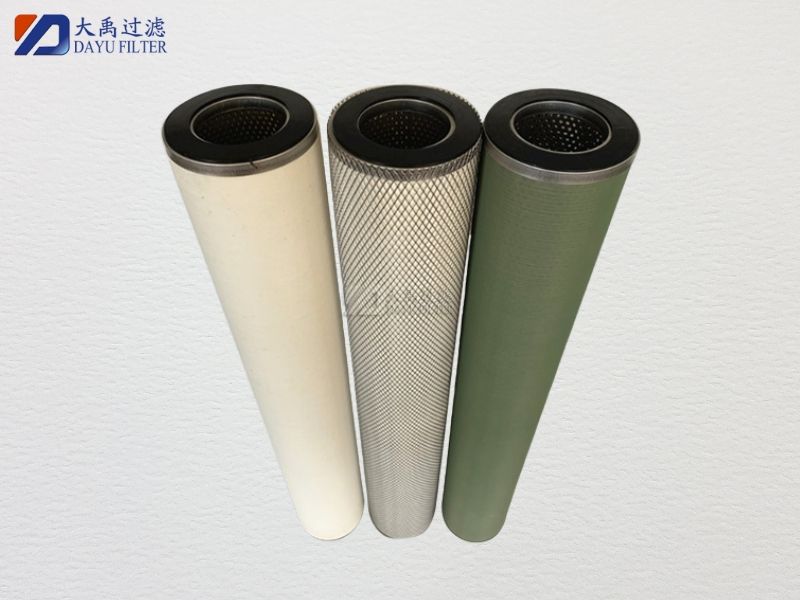

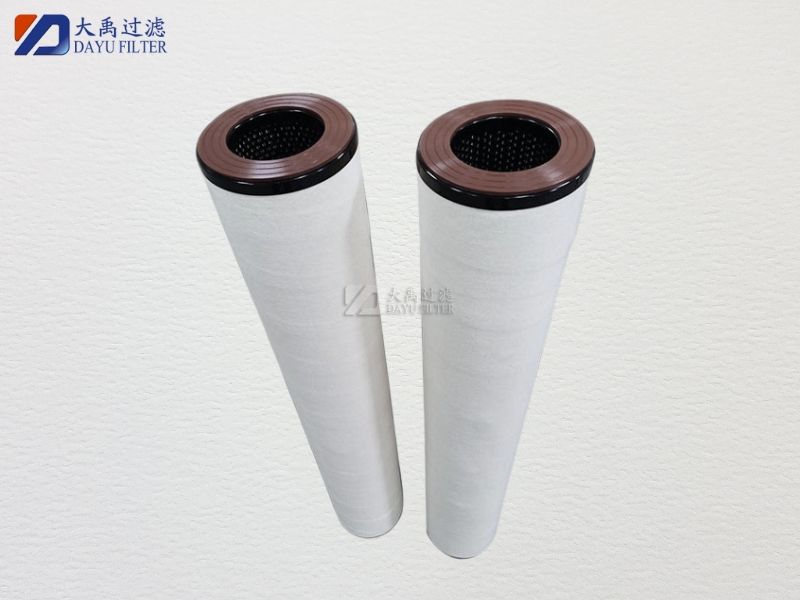

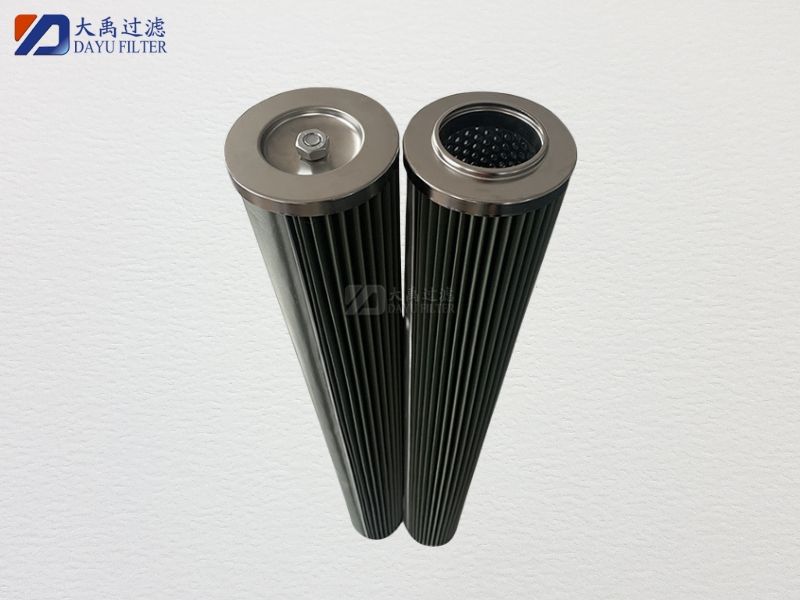

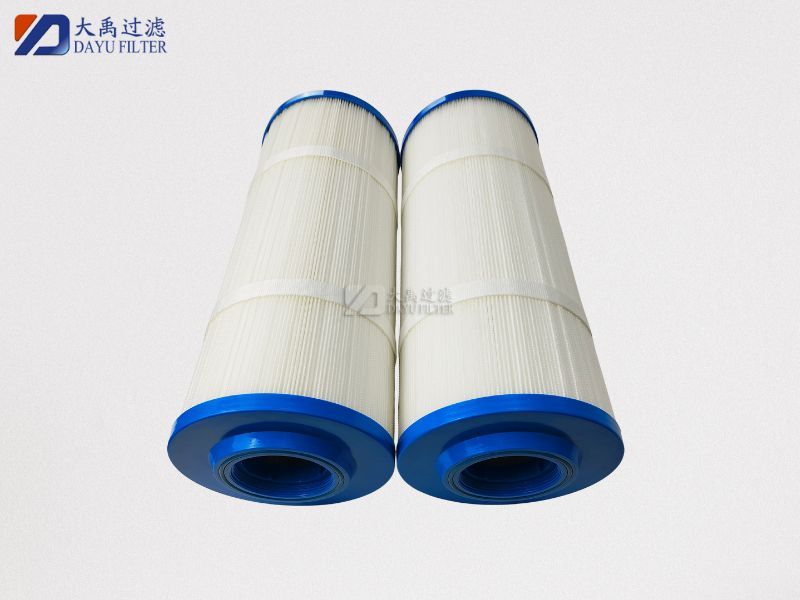

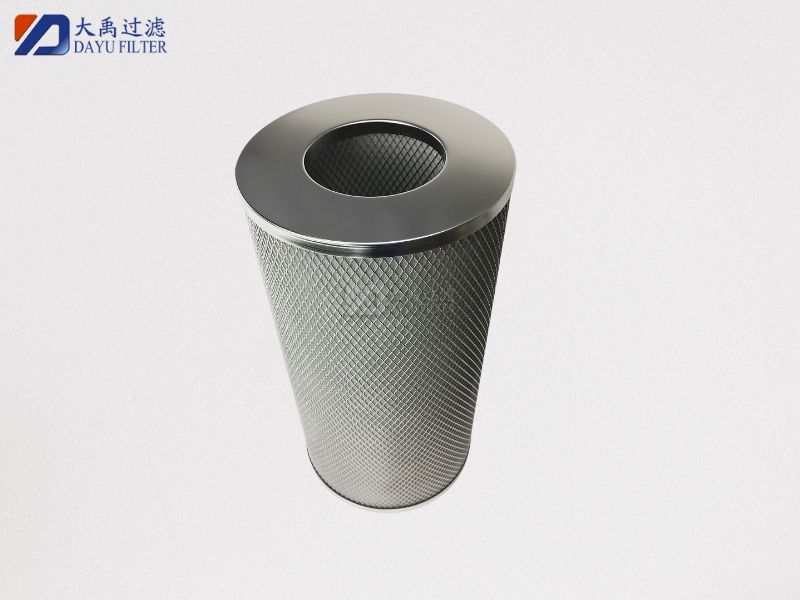

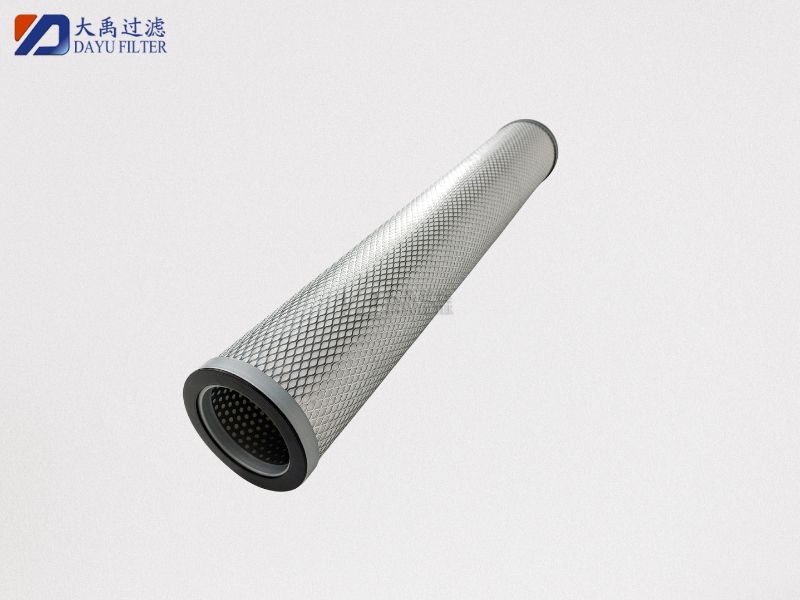

Introduction to Natural Gas Filter CartridgeIn the process of natural gas extraction and pipeline transportation, solid particles and liquid impurities are often carried, causing damage or failure of power equipment and instruments, threatening the safe operation of pipelines. The role of filters is particularly important. It is mainly used for gas purification in various occasions such as natural gas purification plants, long-distance pipeline stations, urban gas transmission and distribution networks, gas power plants, natural gas chemical plants, coking plants, steel metallurgy plants, and non corrosive gas metering.Working principle of natural gas filter: When gas enters the gas chamber, it first collides with the support tube that supports the filter element. Larger solid-liquid particles are initially separated and settle to the bottom of the container under the action of gravity (regularly discharged from the discharge outlet); Then the gas passes through the filter layer from the outside to the inside, solid particles are intercepted by the filter medium, and liquid particles gradually aggregate and grow on the inner surface of the filter element due to the aggregation function of the filter medium. When the droplet reaches a certain amount, it will fall off from the inner surface due to the impact of the airflow and enter the internal flow channel of the filter element to flow out of the material chamber. When the discharge chamber is used, there is also a separation element that can effectively capture liquid droplets to prevent the outlet droplets from being carried, further improving the separation effect. **The clean gas flows out of the filter.A high-precision, high flow filter element and its manufacturing method should adopt a multi-layer composite structure: stainless steel skeleton with different structures, corrosion resistance, excellent structural performance, high welding strength, and low airflow resistance; Different precision filter cartridges adopt different structural methods, and the new matrix mixed fiber increases the contact area of the medium, improving the filtration efficiency. The outer stainless steel mesh forms the * * * layer surface filter, while also providing anti scouring effect; The non-woven protective layer and imported fiberglass composite filter material constitute deep filtration; Polyester or fiberglass filter membranes are sandwiched in the middle layer to form the second layer of filtration; The inner stainless steel mesh provides support; The end of the filter element adopts a multi-layer composite and sealing structure of axial sealing and radial sealing, ensuring that gas will not bypass and the overall filtration effect and reliability.As the amount of gas passing through increases, particles deposited on the filter element will cause an increase in the pressure difference of the filter. When the pressure difference rises to the specified value, it indicates that the filter element has been severely clogged and should be replaced in a timely manner. The process of pollutant loading is the process of blocking the through holes of the coalescing filter element. When the coalescing filter element is blocked by contaminated particles, the number of holes that can pass through the liquid flow decreases, and to ensure the flow rate through the filter material, the pressure difference needs to increase. The initial pressure difference of the filter separator shall not exceed 20KPa, and the replacement pressure difference shall not exceed 100KPa.Natural gas filters can provide initial, medium, high, and different filtration levels for natural gas, effectively protecting the safe and efficient operation of natural gas equipment. They can also manufacture filters and filters suitable for high and low pressure pipelines according to different operating conditions. At the same time, it can also effectively extend the service life of the equipment, better meet people's requirements for product precision, and thus improve the quality of the machine product itself, while greatly saving production costs.