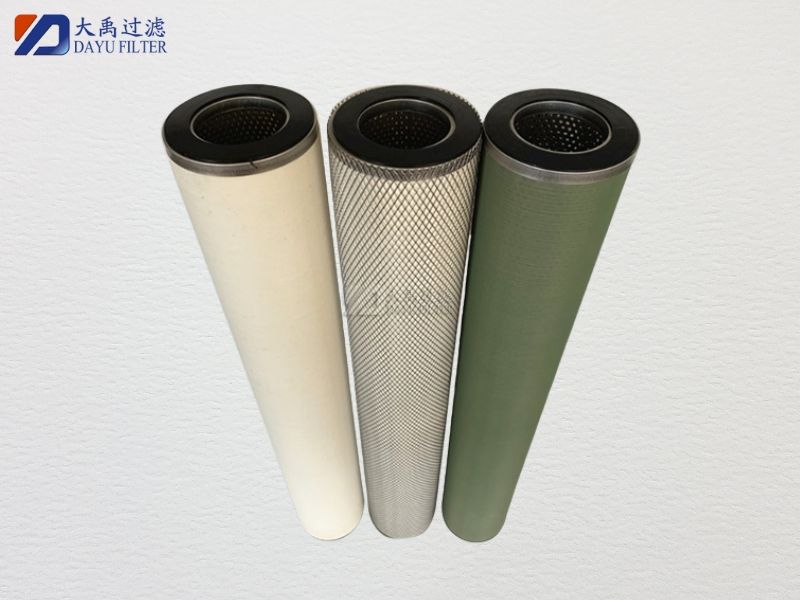

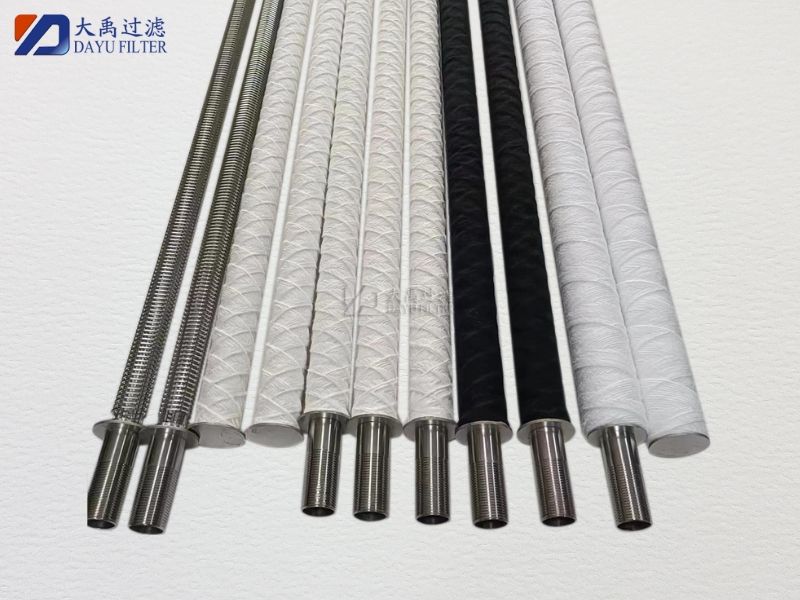

- Product

-

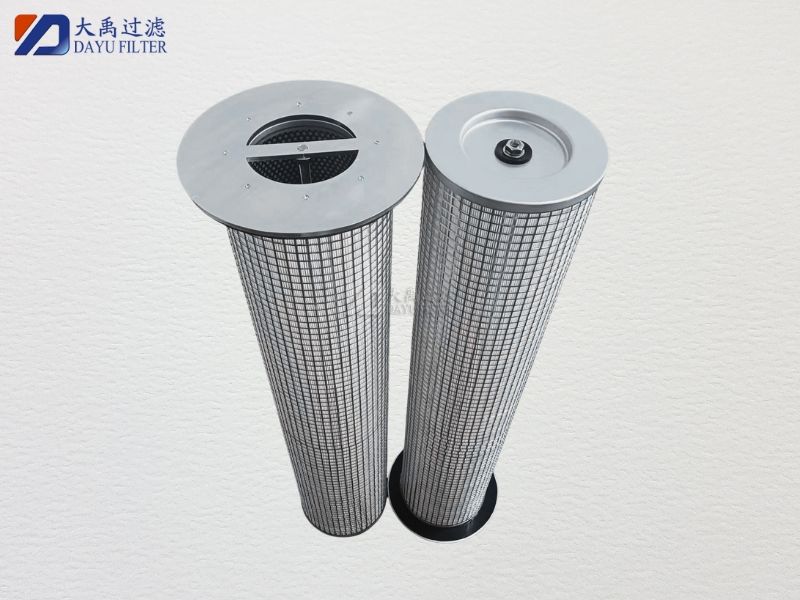

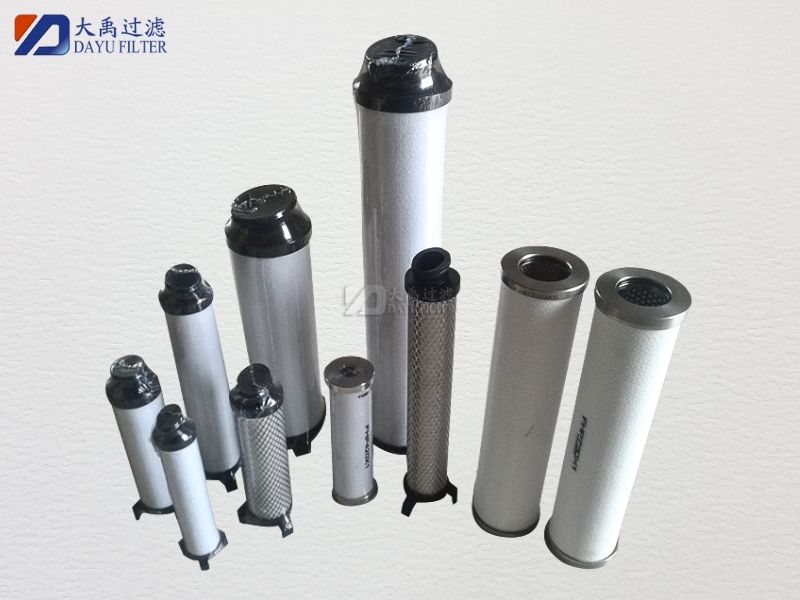

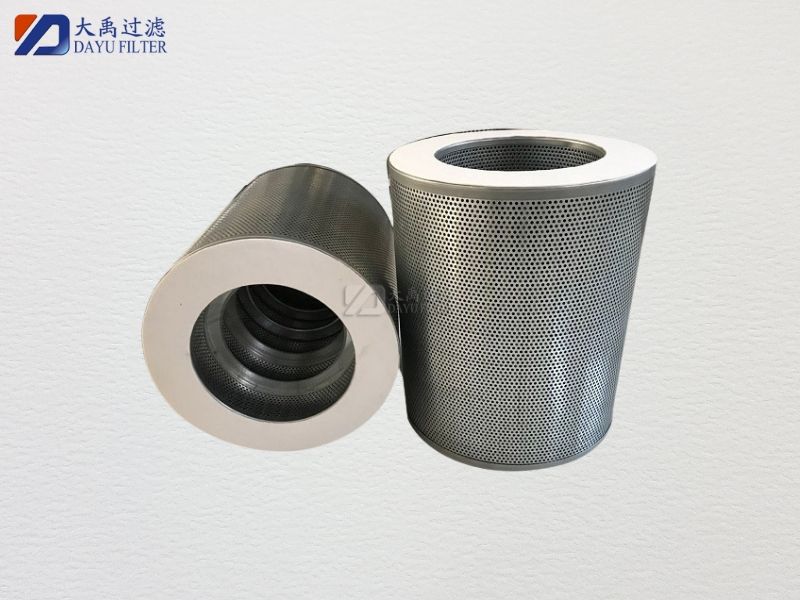

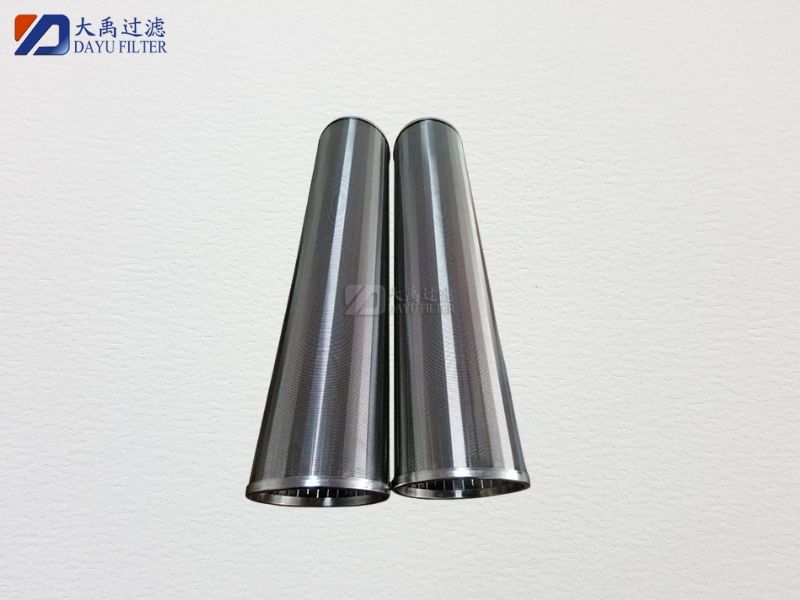

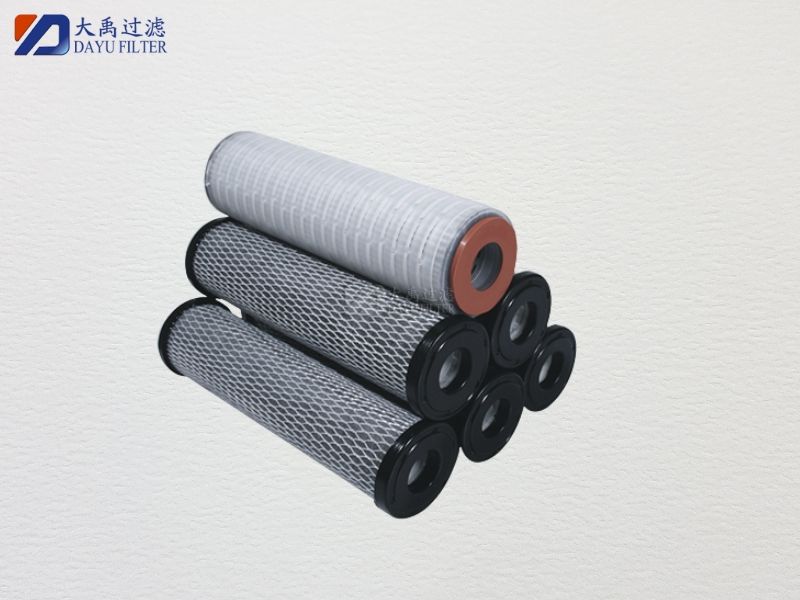

- -Natural gas pipelines

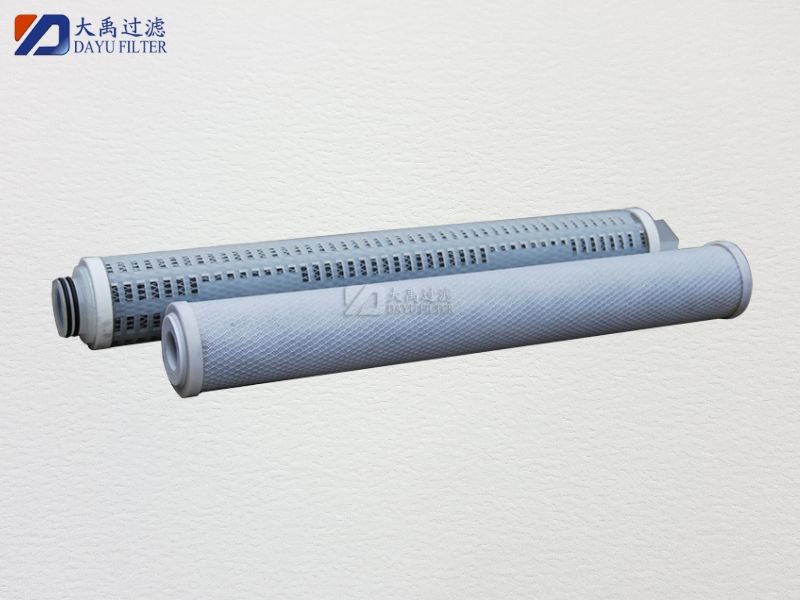

- -Water Treatment Cartridge

- -Regulator station pre-module

- -Polymerized separation

- - low concentration gas

- -Solution Cartridge

- -Stainless Steel Active Carbon

- - Aviation Fuel Coalescing Filter

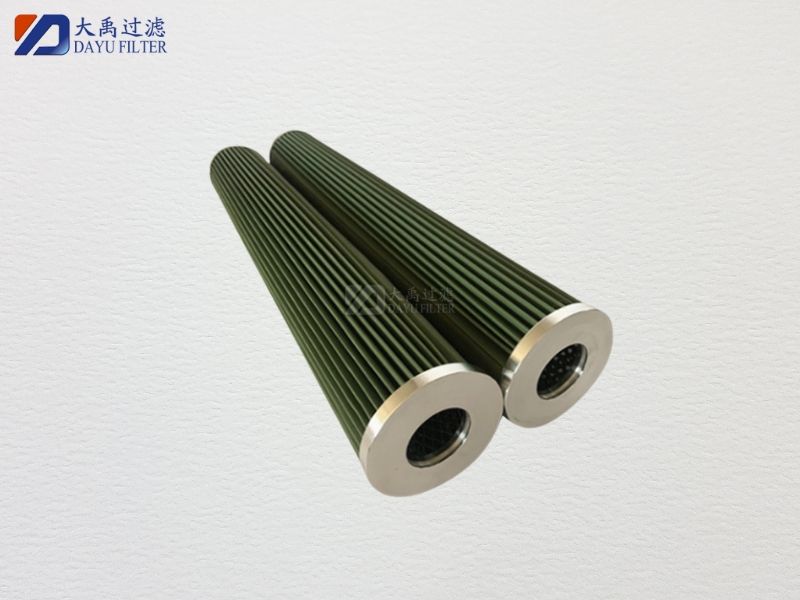

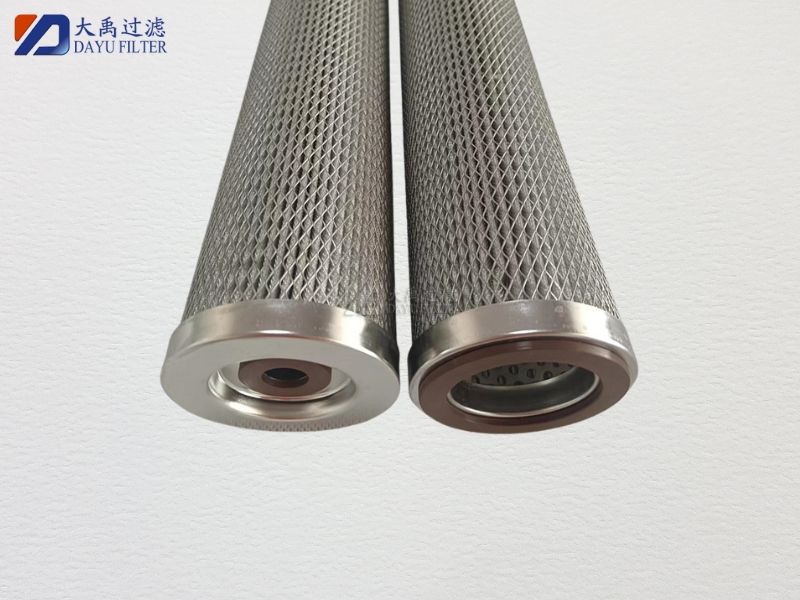

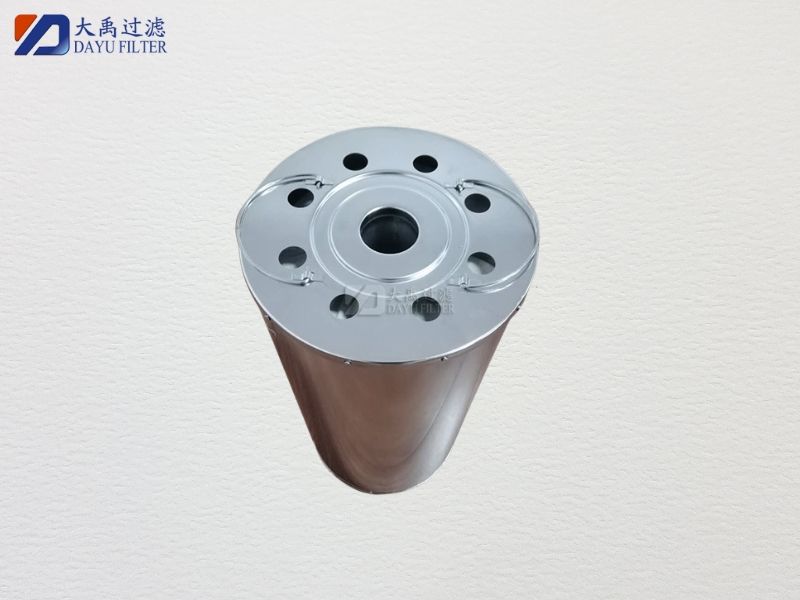

- -Stainless steel sintering

- - Air compressor and dry gas

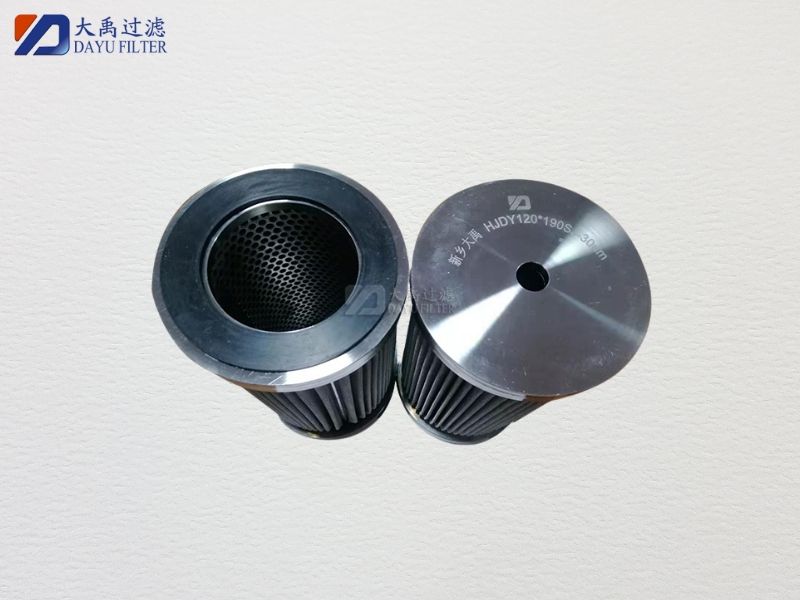

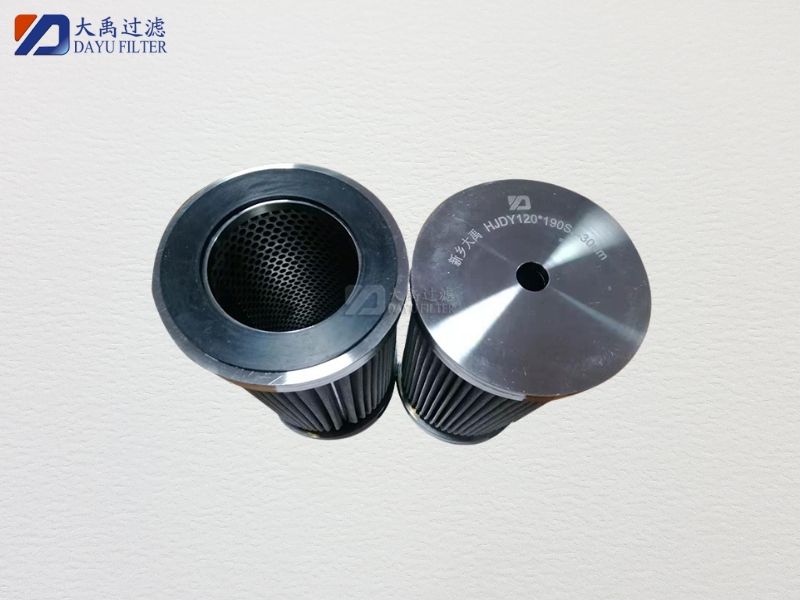

- -Hydraulic, oil systems

- -Filter

Dayu Filtration Equipment

Dedicated to the development, research and development, production, and sales of filtration technology in the fields of water, gas, and oil, we provide you with professional filtration solutions

About us

I am willing to be your soaring wind, helping customers soar and develop!

Dayu Filtration Equipment

Dedicated to the development, research and development, production, and sales of filtration technology in the fields of water, gas, and oil, we provide you with professional filtration solutions

Product

I am willing to be your soaring wind, helping customers soar and develop!

Dayu Filtration Equipment

Dedicated to the development, research and development, production, and sales of filtration technology in the fields of water, gas, and oil, we provide you with professional filtration solutions

news

I am willing to be your soaring wind, helping customers soar and develop!

Dayu Filtration Equipment

Dedicated to the development, research and development, production, and sales of filtration technology in the fields of water, gas, and oil, we provide you with professional filtration solutions

service

I am willing to be your soaring wind, helping customers soar and develop!

Dayu Filtration Equipment

Dedicated to the development, research and development, production, and sales of filtration technology in the fields of water, gas, and oil, we provide you with professional filtration solutions

contact us

I am willing to be your soaring wind, helping customers soar and develop!